EQUIPMENTS

Know the wide range of our equipmentsSOFTENERS

The softening process consist of removing calcium and magnesium ions through ion exchange resins.

Apart from the standard systems, we designs tailor made systems to meet your requirements. They can be classified by the number of resins columns:

– Simplex (one)

– Duplex (two)

– Triplex (three)

– Quadriplex (four)

The control system of these equipments may be chronometric of volumetric, with mechanical or electronic programmer. All the equipments can be adjusted to the specific requirements of each client.

HIDRAFLECK

Softeners fully automatics, build in fibreglass and with FLECK, AUTOTROL or CLACK valves.

HIDRAMATIC

Build in stainless steel columns and design for industries but, can also be used in hotels and hospitals. All regeneration operations are done through pneumatic valves, and controlled by time or treated water flow.

IRON REMOVAL

There are several methods for the removal of iron in water, with the most applied being filtration with specific media (BIRM or CRYSTAL RIGHT). There are limitations to both processes, in relation to the characteristics of the water to be treated.

The configuration of these equipments can be simplex, duplex, triplex ou quadriplex. The control may be chronometric or volumetric. The valves can be FLECK, AUTOTROL, CLACK or pneumatic controlled by automat.

BIRM is more economical, both in investment and maintenance, requiring only water counter-wash, functioning as a normal filter. In addition to iron, it also removes manganese.

CRYSTAL RIGHT needs to be regenerated with sodium chloride. In addition to iron, it also removes calcium, magnesium and manganese.

NITRATE REMOVAL

Denitrification is a process that removes nitrates from the water with ion exchange resins. The filter medium consists of strongly anionic resins, and its regeneration is carried out with sodium chloride.

The configuration of these equipment can be simplex, duplex, triplex or quadriplex type and with volumetric or chronometric control.

The valves can be FLECK, AUTOTROL, CLACK or pneumatic type commands by an automat.

FILTRATION

Automatic filtration systems of various types and can be loaded with different types of media, according to the intended purpose.

In this type of equipment a periodic washing is necessary to eliminate the suspended matter that is retained in the filter bed, in order to restore the capacity of the filter.

Like softeners, the automatic washing of these filters can be controlled chronometrically or volumetrically, having simplex, duplex, triplex and quadriplex configurations.

FILTRATION MEDIA

Multimedia filters are designed to remove particulate matter and are composed of several layers of filter media, with different granulometry or even filter media, in order to ensure a good efficiency for each type of Water and intended purpose.

FILTER AG is a granulated filter media, highly effective in the removal of suspended matter, being composed of small porous grains with irregular surface.

Chemically, FILTER AG is a dehydrated silicate, presenting important advantages over traditional sand filters, such as:

-Increased filtration capacity and clarity of water, allowing you to work with smaller units

-Because it is a lighter, porous material, it allows you to work with flow rates and lower backwash times, saving on water consumption

The active carbon is a filter medium composed of black granulated coal, used to eliminate odors, taste and color of water.

A very frequent application of activated charcoal is the removal of chlorine after a disinfection process, which changes the taste and smell of the water.

This filter media is applicable within a wide range of pH values, but the water should not contain oils or fats and a minimum content of suspended matter and iron.

These filters consist of a stable granule of calcium carbonate and magnesium, NEUTRALITE, which restores to water its minerals and equilibrium pH, eliminating the existing carbonic acid. The result is a chemically balanced treated water.

The volume of NEUTRALITE depends on the existing carbonic acid and the flow rate of water to be treated, and laboratory tests are usually performed for its size

NEUTRALITE is a filter medium that is consumed, and it is necessary to carry out periodic refills.

DEMINERALIZATION

Demineralization consists of the process of removing salts from water leading to a water of high purity.

DEMINERALIZER

Each demineralization unit is composed of two resin columns: one cationic and one anion. The regeneration of the resins is made with hydrochloric acid and sodium hydroxide, respectively.

Within the possible configurations, there are simplex systems (a unit composed of two columns) and duplex (two units composed of two columns each).

The control valves can be SIATA or pneumatic type controlled by automaton

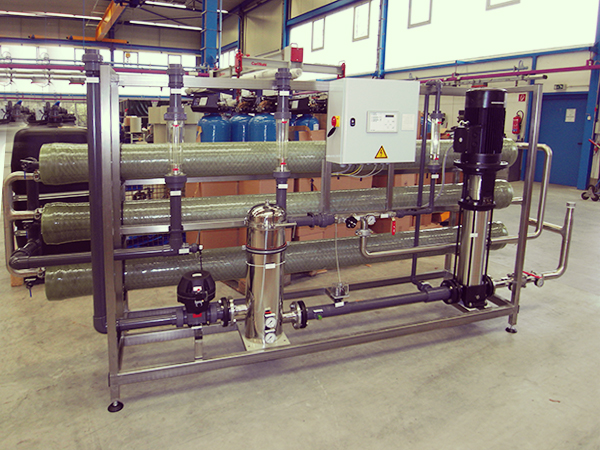

REVERSE OSMOSIS

Reverse osmosis is a newer technique that consists of the diffusion of water, at high pressure, through synthetic membranes. Applying a pressure higher than the osmotic pressure, water is forced through semipermeable membranes in the opposite direction to the natural osmosis.

Like demineralization, reverse osmosis produces high quality water, but with the great advantage of not using chemicals or neutralizing effluents.

ULTRAPURE WATER

For the production of ultrapure water a polishing step is carried out after a demineralization process, the polishing process can be:

– Mixed bed resins (MB)

– Electrodeionization (EDI)

The most common ultrapure water production systems are complete systems consisting of osmosis plus EDI supplied in skid.

MIXED BED

It consists of one or more columns containing both strong cationic and anionic resins simultaneously.

EDI

EDI (Electrodeionization), used most of the cases after a reverse osmosis. Due to the absence of chemicals, there are no problems of neutralization or waste disposal.

ULTRAFILTRATION

Ultrafiltration is a process driven by pressure differentials that is used for the selective elimination of suspended matter, particles, large macromolecules, colloidal matter or microorganisms, but does not eliminate ions or dissolved matter as is the case with reverse osmosis.

Ultrafiltration systems have a number of advantages over conventional filtration, such as lower chemical consumption, higher contaminant elimination efficiency, better and more consistent filtrate quality, more compactness and simpler automation.

These systems require periodic chemical cleaning to restore membranes, which can be found commercially in various configurations.

STERILIZATION

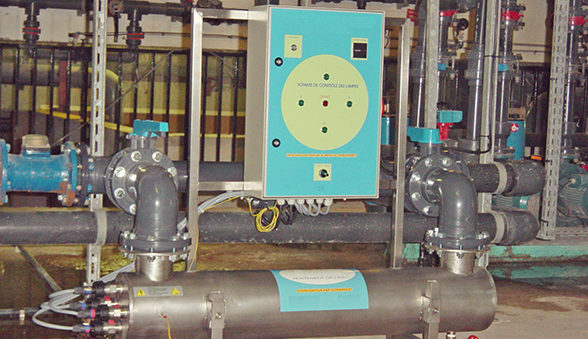

ULTRAVIOLET

The method consists of passing the water through an ultraviolet ray beam, which will affect the microorganisms, inhibiting their cellular activity, the disinfection is immediate, not requiring contact time.

Due to the absence of chemicals, there is no change in taste, odor or physico-chemical characteristics of the water.

CHEMICAL DESINFECTION

In addition to the more traditional dosing solution (hypochlorite solution), we also present ozone system and chlorine dioxide systems which include a chlorine dioxide generator, from a dilute solution of hydrochloric acid and sodium chlorite.

DOSING SYSTEMS

For a controlled and effective dosage we propose complete systems, including metering pumps, metering tanks and counters.

We present a wide range of each of the components in order to propose a system adapted to the needs.

PUMPING GROUPS

We present a wide range of pumps and their accessories equipment and wear parts.

- Fixed and variable speed circulating pumps

- Single-stage pumps

- Vertical and horizontal multicell centrifugal pumps

- Pressurizing systems with one or more pumps

- Submersible pumps

- Sewage pumps

CARTRIDGE/SLEEVE FILTERS

Transparent cups are available to facilitate visual inspection of the condition of sleeves / cartridges and the level of deposits to be purged.

Optional accessories and spare parts to provide the ability to customize each unit for individual applications or to add in multiple units on a single system to provide solutions to certain water quality problems.

In addition to sleeve filters, and PP cartridges can still use polyphosphate crystals or activated carbon for more specific applications.